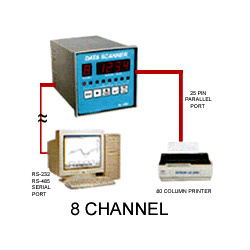

FEATURES

- Used latest micro controller based technology for better accuracy

- 8 Channel fixed input for all thermocouple, J, K, R, S, T, E, B, N programmable by user & RTD (PT-100), 4-20mA, 0-10 VDC factory settable

- Easy on-line field calibration by front panel membrane keypad

- Field programmable channel scan time 1 to 59 sec.,

- Logging interval 1 to 9999sec & Printing Interval 5 to 9999 sec.

- Field programmable Delay time 1 to 99 sec. for Relay Output

- Optional RS-232 / RS-485 Modbus Serial Port

- Optional Parallel / USB Printing Port

APPLICATIONS

- ISO Certification records, Validation process certifying

- Pharmaceutical process validation with graph & excel report in Autoclaves

- Online profile recording for Oven & BOD, Incubator, Humidity Chamber

- Winding temperature of generators, Bearings, motors, transformers

- To know heat Profile in furnace, foundries for Heat treatment application

- Primary & auxiliary temperature scanning of boiler

- Chemical & Hazardous area where data monitoring is essential

- Room Mapping in Pharmaceutical

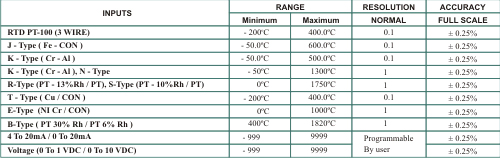

Technical Specifications

| Input |  |

| Display L.E.D. IndicationSet Point Control actionRelay Output SettingScan Time Print IntervalLogging IntervalMemoryMonitoring SensorOpen / Under / OverSupply VoltageOperating TemperatureEnclosure DetailsProtection ClassCabinet MaterialCable EntryDimensionCutoutMountingWeightOptional | 4 digits of 13 mm height Red L.E.D display for ‘Process Value’ indication 1 digit of 13 mm height Red L.E.D display for ‘Channel Number’ indication 8 Nos Red L.E.Ds of 3 mm for Alarm Indications i.e. AL1 & AL 2 2 independent set points for each channel with 2 common relay outputs & programmable latch / non-latch facility for 2 common relays & Alarm indications HI – LO, LO – Very LO, HI-Very HI Control action logic; programmable by user 1 NO/C/NC Relay Contact Rated 230VAC/5A for Relay-1 (AL1) & Relay-2 (Al2) Setting by 5 feather touch keypad on front panel ‘MODE’, ‘SHIFT’, ‘INC’, ‘ENT’, ‘PRN / ACK’ 1 to 59 sec scan/scroll time between each channel; programmable by user (Optional) 5 to 9999 Sec for Direct print out on 24 / 80 / 132 Column Dot matrix Printer 1 to 9999 Sec log interval for data logger model; programmable by user Max. 5000 readings storing capacity for all 8 channel in Data Logger model Memory saturation, Memory Scrolling (FIFO) & Online PC interface available in Data Logger model Temperature sensor ‘Break / Open’ display shows ‘oPEn’ indication Under range ‘undr’. Over range ‘OuEr’ indication for RTD & all Thermocouple I/Ps 230 VAC ±10%, OR 110 VAC ±10% OR 24 VDC OR 12 VDC – 40 To 85 oC Relative Humidity : Below 95% non condensing PANEL MOUNTING (PM) Terminal connector |

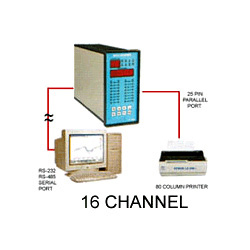

FEATURES

- Used latest micro controller based technology for better accuracy

- 16 Channel fixed input for all thermocouple, J, K, R, S, T, E, B, N programmable by users, and Fixed Inputs for RTD (PT-100/CU53), 4-20mA, 0 – 10 VDC factory settable

- Easy on-line field calibration by front panel membrane keypad

- Field programmable channel scan time 1 to 59 sec., Logging interval 1 to 9999 sec & Printing Interval 5 to 9999 sec.

- Field programmable Delay time 1 to 99 sec. for Relay Output

- Optional RS-232 / RS-485 Modbus Serial Port Optional Parallel / USB Printing Port

- Opt

APPLICATIONS

- ISO Certification records, Validation process certifying

- Pharmaceutical process validation with graph & excel report in Autoclaves

- Online profile recording for Oven & BOD, Incubator, Humidity Chamber

- Winding temperature of generators, Bearings, motors, transformers

- To know heat Profile in furnace, foundries for Heat treatment application

- Primary & auxiliary temperature scanning of boiler

- Chemical & Hazardous area where data monitoring is essential

- Room Mapping in Pharmaceutical

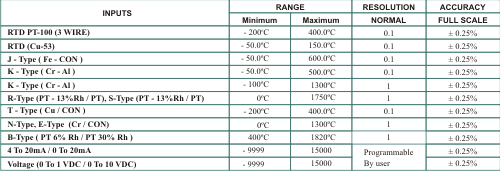

Technical Specifications

| Input |  |

| Display L.E.D. Indication Set Point Control action Relay Output Setting Scan Time Print Interval Logging Interval Memory Monitoring Sensor Open / Under / Over Supply Voltage Operating Temperature Enclosure Details Protection Class Cabinet Material Cable Entry Dimension Cutout Mounting Weight Optional | 5 digits of 13 mm Height Red L.E.D display for ‘Process Value’ indication 2 digit of 13 mm Height Red L.E.D display for ‘Channel Number’ indication 32 Nos Red L.E.Ds of 3 mm for Alarm Indications Al1 & AL 2 Individual for each channel 2 independent set points for each channel with 4 common relay outputs & programmable latch / non-latch facility for 4 common relays & Alarm indications HI – LO, LO – Very LO, HI-Very HI; programmable by user 1 NO/C/NC Relay Contact Rated 230VAC/5A for four Relay Setting by 8 keys on front panel ‘MODE’, ‘SHIFT’, ‘INC’, ‘ENT’, ‘PRN’, ‘ACK’, ‘ESC’, ‘HOLD’ 1 to 59 sec scan/scroll time between each channel; programmable by user (Optional) 5 to 9999 Sec for Direct print out on 24 / 80 / 132 Column Dot matrix Printer 1 to 9999 Sec loggin interval in data logger model; programmable by user Max. 3000 readings storing capacity for all 16 channel in Data Logger model Memory saturation, Memory Scrolling (FIFO) & Online PC Interface available in Data Logger model Temperature sensor ‘Break / Open’ display shows ‘oPEn’ indication Under range ‘undr’. Over range ‘OuEr’ indication for RTD & all Thermocouple I/Ps 230 VAC ±10%, OR 110 VAC ±10% OR 24 VDC OR 12 VDC -40 To 85 oC Relative Humidity : Below 95% non condensing PANEL MOUNTING (PM) IP – 40 MS, Aluminium powder coated Terminal connector 192(H) X 96(W) X 200(D) in mm Panel mounting 1.5 Kg Isolated RS-232 / RS-485 Serial Port with MODBUS RTU Protocol output |