Modern production processes need intelligent heat. And infrared thermal technology is efficient and precise. Today nearly every product that is manufactured comes into contact with infrared radiation during its manufacture. This trend is growing. Consequently, it is even more important that the correct heater is selected for every application. Infrared heaters cover the total spectrum of technologically-available wavelengths; we can help you find the optimal light source to suit your specific process application. Perfectly matched infrared lamps allow heating processes to be carried out at great efficiency with the right amount of energy. Reliable and reproducible manufacturing processes save money.

APPLICATIONS

- PET perform heating in stretch blow molding machines

- Printing Ink drying in offset machines

- Screen-printing curing on T-shirts and textiles

- Powder coating curing

- Impregnation plants

- Rubber coated drying

- Soldering fusing in PCB industries

- Sterilizing/mirror coating drying in glass industries

- Paint baking

- Paper coating drying

- All type of lamination

- Preheating prior to embossing

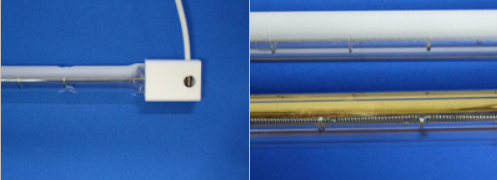

Various Type of Quartz Infrared Lamps

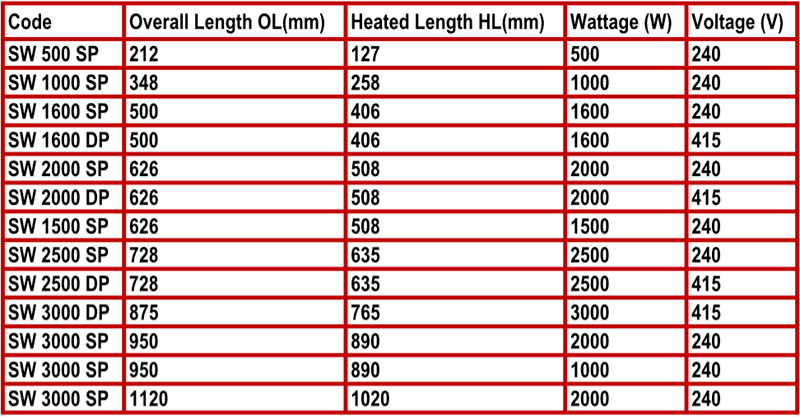

Some Standard Short Wave Infrared Sizes

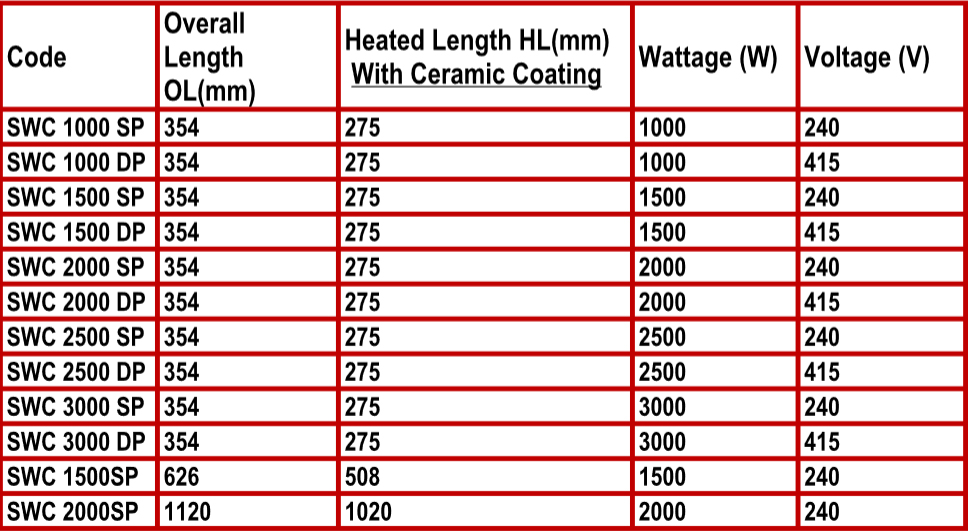

Some Standard Short Wave Infrared Sizes with Half Ceramic Coating

OTHER SIZES CAN BE OFFERED ON REQUEST

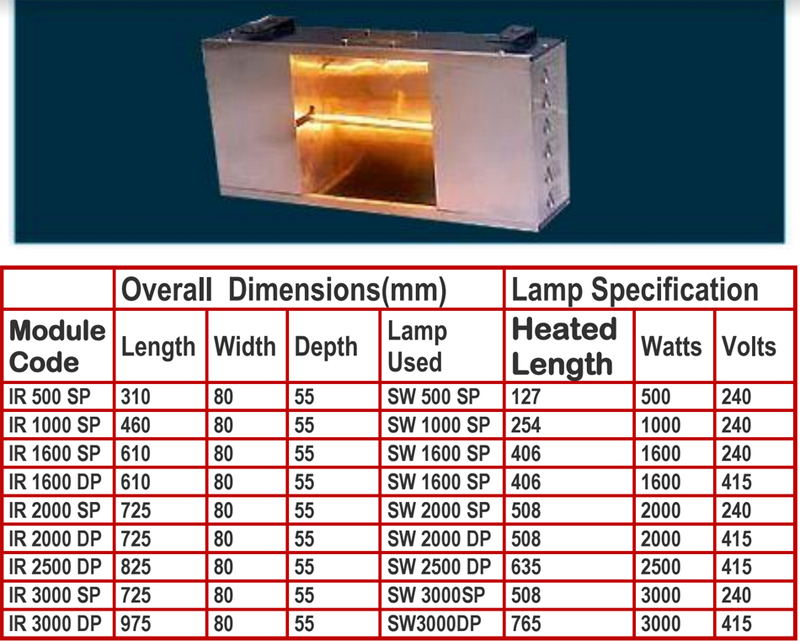

WITH MODULE

OTHER SIZES CAN BE OFFERED ON REQUEST

Infrared Heating Technology

Technology that harnesses the power of infrared radiation can provide a powerful and efficient process heat source.Infrared heaters with IR technology are well-suited to a wide variety of applications and designed to transmit large amounts of energy quickly and with high efficiency. The particular wavelength of the infrared radiation has a critical effect on the effectiveness of the heating process. Infrared heaters, which are optimally matched to the materials to be heated, can provide energy savings of up to 50% over other technologies. Infrared heaters and infrared heating technology offer significant advantages: heat exactly where it is needed, with the optimum wavelength for the product and in line with the process. Dydac offers a complete range of heaters.We offer and design radiant heating products and equipment for industrial processes using proven infra red technology. This site offers information on our company and our complete product line including radiant heaters and heating equipment for process applications. We offer a full spectrum of high and low intensity heat for industrial processesAs energy costs keep rising, you may consider efficiency measures to save energy and curb energy costs. Process heating accounts for a high percentage of energy use for most industries. Infrared heating technology, a clean and efficient heat transfer measure, is a great solution for your business.

Method of Heat transmission

- Conduction

- Convection

- Radiation

Features:

All of our emitters can be coated with a layer of gold or ceramic as reflectors. The gold/ ceramic coating can concentrate the heat, increasing the effectiveness of the heat output. The emitters with coating are highly economical, converting practically all the consumed electrical power into heatFor the emitters with high watt density or the surface temperature of the tube above 800¢XC , we suggest to use ceramic coating as reflector because the temperature resistance is up to 1000¢XCIn addition to 180¢X (half-tube) coating, we also manufacture 270¢X coating or other customer specified degreesAs energy costs keep rising, you may consider efficiency measures to save energy and curb energy costs. Process heating accounts for a high percentage of energy use for most industries. Infrared heating technology, a clean and efficient heat transfer measure, is a great solution for your business.In general, conduction and convection require heat-transmitting media such as solid, liquid, or gas. However, in the process of heat transmission by conduction and convection , most of heat is wasted. Radiation has higher thermal efficiency by directly transmitting the heat to the object without requiring any media.Infrared radiation, one of the electromagnetic radiations, travels in a straight line at the speed of light from the heat source. In the process of travel, the energy of infrared radiation is not absorbed by air and directly transmits the heat to heated substance from the heat source; therefore infrared radiation is a very efficient source of radiant energy. Infrared radiation can save the process time and reduce the energy costs when applied in the industrial use.

Comparison of Different Heating Source

| Hot Air | Tubular Metal Heater | Medium wave I.R. Quartz Emitter | Short Wave I.R. Quartz Emitter | |

| Physical Strength | medium | high | medium | medium |

| Accuracy of Temperature Control | Low | Medium | Medium | High |

| Dust Pollution | High | Medium | Low | Low |

| Radiant Efficiency | Low | Medium | High | High |

| Max. Temperature of element surface | 400 ¢XC | 700 ¢XC | 600 ¢XC | 750 ¢XC |

| Life | 2 year | 1-2 year | 1-2 year | 5000 hrs |

| Heat Up | very slow | slow | fast (1-2 mins) | very fast (1-2 secs.) |

| Infrared Emission | Long Wave | Long Wave | Medium Wave | Short Wave |